Millplus IT, DMG DMU80T, G7

Change the work plane in 4 and 5 axis machines using G7

This is totally new to me, I have use the machine on and off in a couple of

years but never had the energy to take the G7 function to my mind.

It can be a big deal to handle specially on the machine with a rigid table,

indexing mill head and rotating C-axis..

This indexing spindle head can be turned 0 to -90 degrees only.

With the G7 function you can order the machine to mill/drill of the opposite

face of the part where the milling head can not reach. The smarthead of

machine knows that it need to repositioning the C-axis to reach the face

automatically, brilliant, I know. Then comes the question, what happen to

the zero point, axis and axis directions and so on.

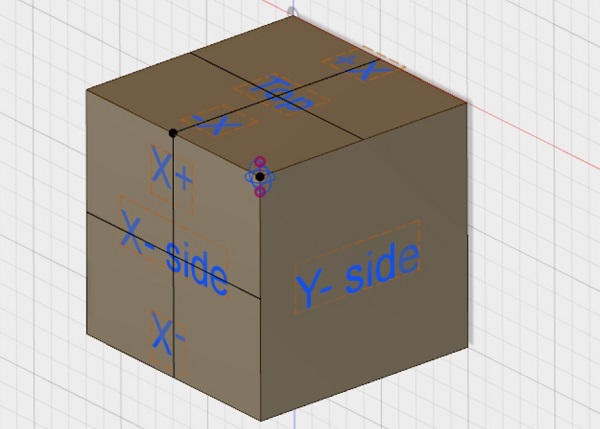

I will show an easy method to start with the top plane on the workpiece and

change to the nearest plane (Right side/ X-) and what happens to the axis

and axis directions.

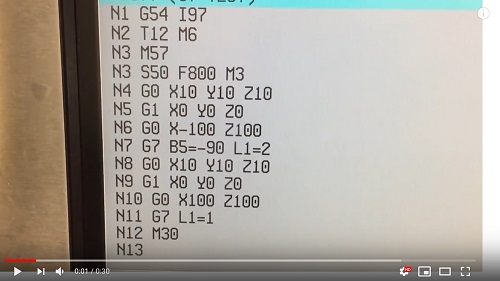

The program

G54 I97

T12 M6 (drill)

S1000 F200 M3

M57 (on our machine, unlock head angle over -31deg)

G0 X10 Y10 Z10 (positions before)

G1 X0 Y0 Z0 (touch the Zeropoint with the tool)

G0 X-100 Z100 (safe position before Indexding the head)

G7 B5=-90 L1=2 (turn the coordinate system to the side of the workpiece)

G0 X10 Y10 Z10 (position before)

G1 X0 Y0 Z0 (touch the same zero on the right side of the workpiece)

G0 X100 Z100 (Go up in X+ and to the right in Z+, Wierd?)

G7 L1=1 (Leave G7, see the late comment down below)

M30

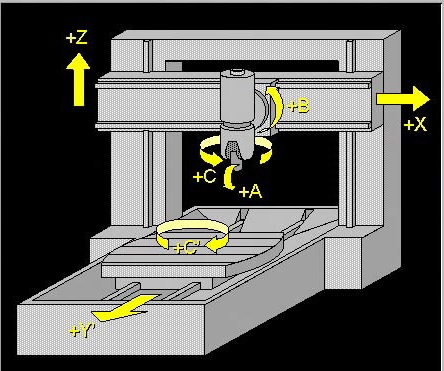

The machine axis, C-axis is the table not the spindle and I'v got no

A-axis..

Change the work plane in 4 and 5 axis machines using G7

This is totally new to me, I have use the machine on and off in a couple of years but never had the energy to take the G7 function to my mind.

It can be a big deal to handle specially on the machine with a rigid table, indexing mill head and rotating C-axis..

This indexing spindle head can be turned 0 to -90 degrees only.

With the G7 function you can order the machine to mill/drill of the opposite face of the part where the milling head can not reach. The smarthead of machine knows that it need to repositioning the C-axis to reach the face automatically, brilliant, I know. Then comes the question, what happen to the zero point, axis and axis directions and so on.

I will show an easy method to start with the top plane on the workpiece and change to the nearest plane (Right side/ X-) and what happens to the axis and axis directions.

The program

G54 I97

T12 M6 (drill)

S1000 F200 M3

M57 (on our machine, unlock head angle over -31deg)

G0 X10 Y10 Z10 (positions before)

G1 X0 Y0 Z0 (touch the Zeropoint with the tool)

G0 X-100 Z100 (safe position before Indexding the head)

G7 B5=-90 L1=2 (turn the coordinate system to the side of the workpiece)

G0 X10 Y10 Z10 (position before)

G1 X0 Y0 Z0 (touch the same zero on the right side of the workpiece)

G0 X100 Z100 (Go up in X+ and to the right in Z+, Wierd?)

G7 L1=1 (Leave G7, see the late comment down below)

M30

The machine axis, C-axis is the table not the spindle and I'v got no A-axis..

The machine has been programmed to turn the tool from top zero to X- side zero

on the edge

It should simulate a drilling on the top and the 90 degrees X- side according to

the picture

The video will show that the program vill meet the zero point from 0 deg and

-90deg

Charming G-code, no doubt on that.

But the machine make the wierd stuff, When you are in the -90deg, the axis

shifts.

You got the Z- axis right in to the workpiece (pic). thats our old (real) X+

Our new X is our old Z, you got X+ for tool up from the table and X- for tool

down to the table, Y stays the same.

I'v learn from a wise man that if you go from top of the workpiece to the

left/X-side, just tilt the workpiece that way in your mind, then the axis make

sense, tilt your computer to the right and you see it. the workpiece zero point

is the same all on the workpiece.

still learning on this.

Is the exemple hard to understand? yeah, it is and I made this most to

understand it myself.

Please leave a comment if you got issues with it, you can help me change the

content so it will help any one who need the instruction in the best way.

The blog is the way to reach me now, goto blog