CNC, what are we doing with that?

Coordinates

CNC-system are used to make some kind of machine to move between certan coordinates.

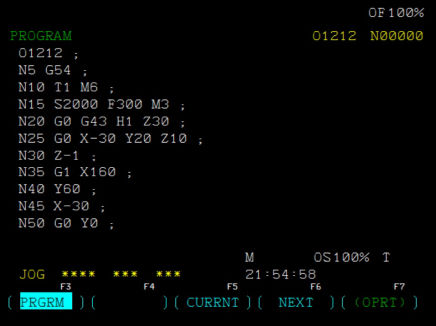

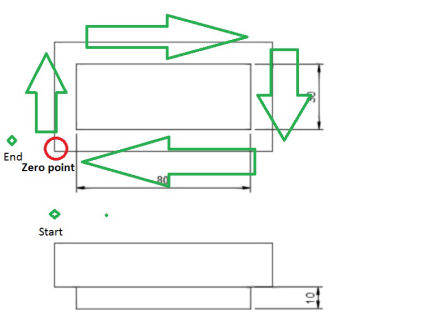

The thing you do (see the pic.):

For starters, you stand on point X0, Y0 in this coordinate-system. You want to move to the green (2,3)-position, you just tell the CNC to "(goto)(point) X2 (and) Y3"

And if you want to travel on to the red point (-3,1):

Tell the CNC to "(goto)(point) X-3 (and) Y1"

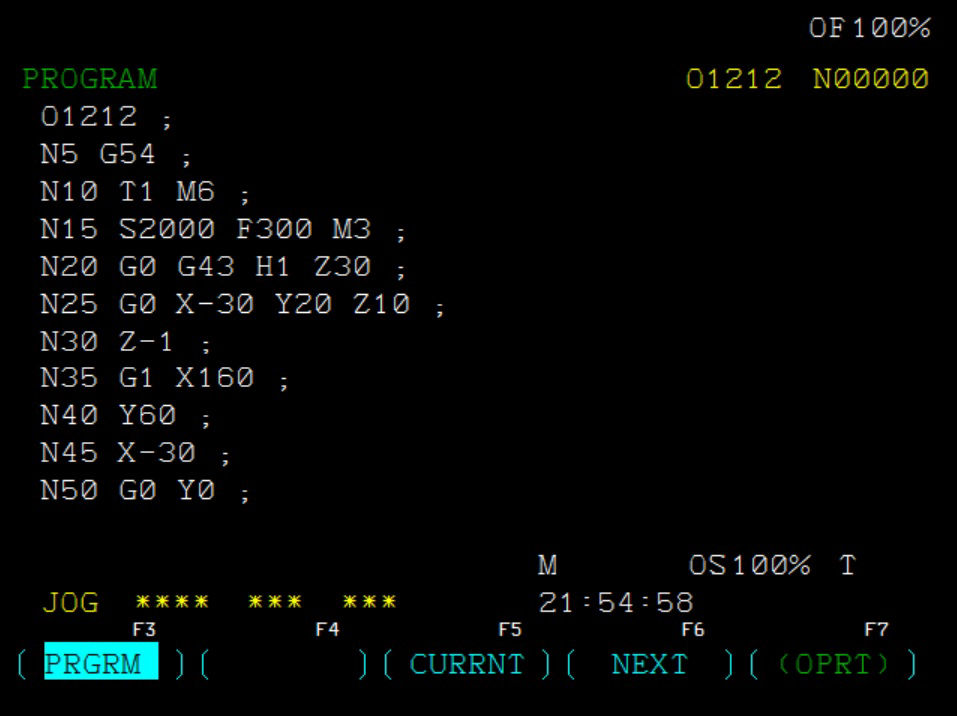

Codes

That's not exactly how you do it, the things between (....) is only there to show how the machine actually do it, you need to add these in another format.

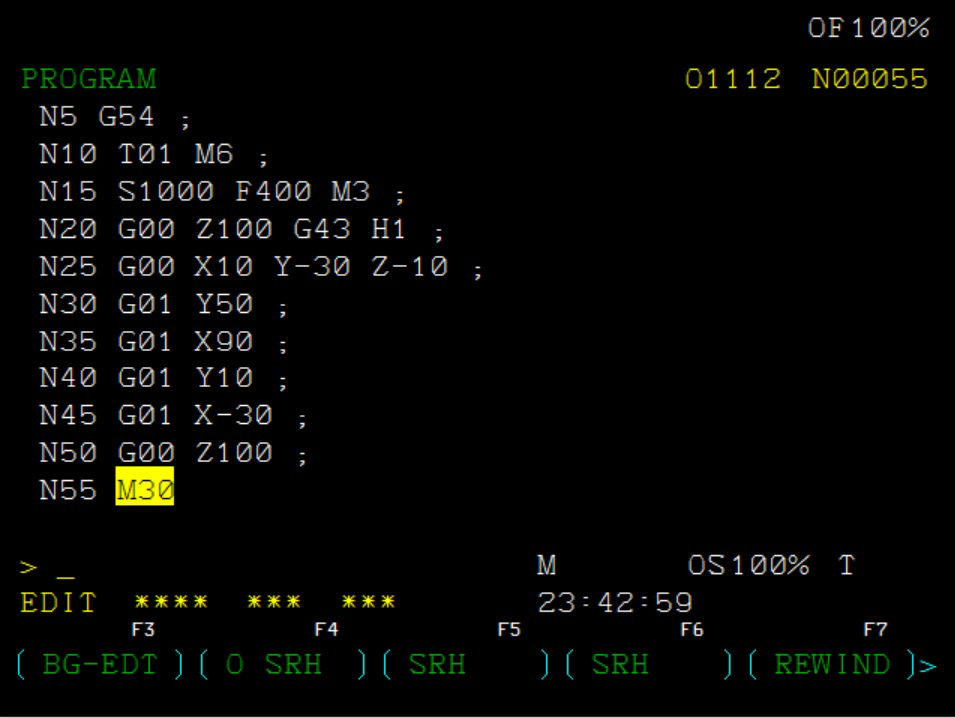

You need to command the CNC to do thing with something that calls G and M codes.

If I add those to the above shown exemple it will be:

G01 X2 Y3.

G01 is a G code and tells the machine to move with a certan speed to the points shown.

G codes are used to control a massive amount of funktions, but some are more used and important than others.